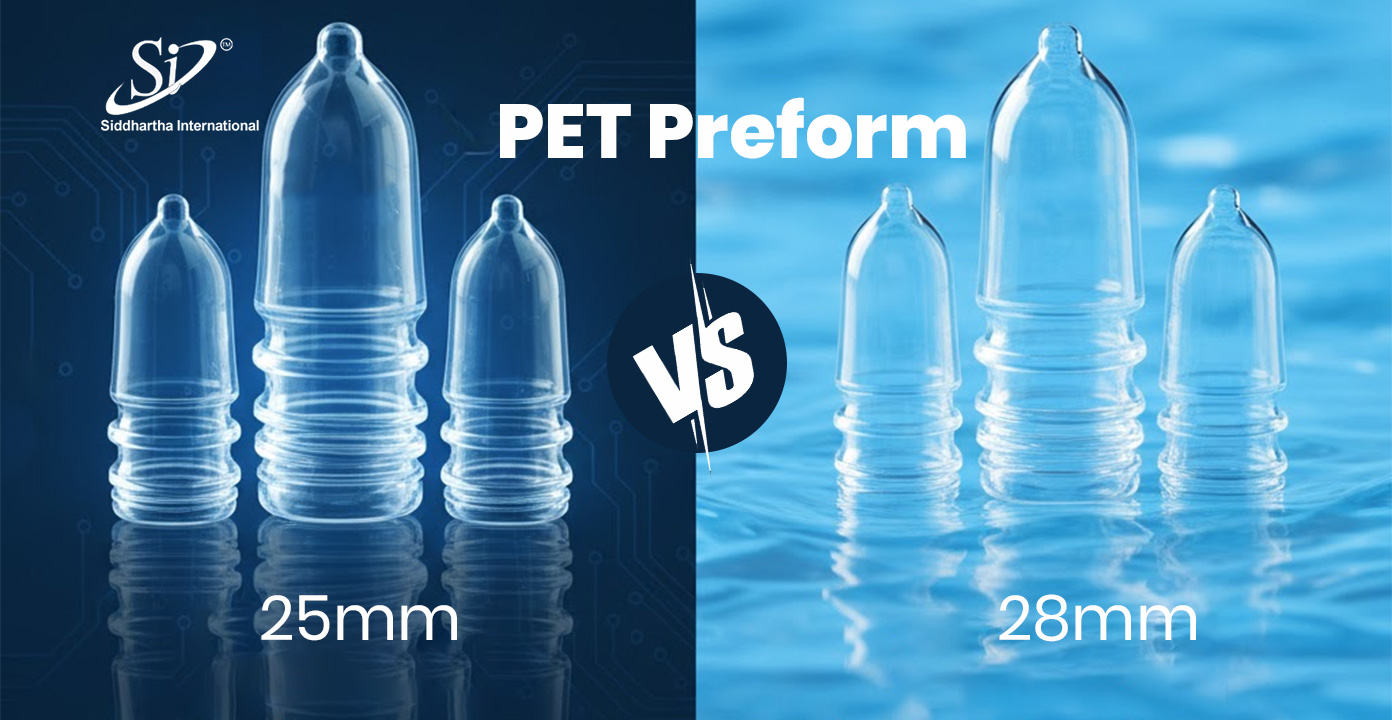

In today’s competitive beverage and liquid packaging industry, selecting the correct PET bottle preform size is no longer a simple technical decision. The choice between a 25mm PET preform and a 28mm PET preform directly influences packaging cost, bottle performance, production efficiency, brand positioning, sustainability goals, and consumer experience.

This detailed article serves as a complete PET preform selection guide. It explains the PET preform size difference, manufacturing considerations, performance impact, and application suitability. If you are wondering which PET preform is better for your business, this guide will help you make a confident, data-driven decision.

A PET preform is an injection-molded product made from polyethylene terephthalate (PET). It serves as the base material that later expands into a bottle using Injection Stretch Blow Molding. The preform’s geometry—especially the PET preform neck finish—defines the final bottle’s strength, usability, and sealing performance.

Key technical parameters include:

Once molded, the neck finish remains unchanged during blowing, which is why neck finish diameter importance in PET bottles is so critical.

View Products

View Products

The PET preform neck finish determines compatibility with PET bottle cap size, sealing integrity, carbonation retention, and pouring convenience. Global beverage brands strictly follow bottle neck finish standards to ensure uniformity across supply chains.

Among all standards, 25mm and 28mm neck finishes dominate global PET packaging solutions.

The 25mm PET preform is commonly used for lightweight bottles, especially in the still water segment. It supports material reduction strategies while maintaining adequate mechanical strength.

These advantages make the 25mm option popular among manufacturers focused on high-volume production and sustainability.

The 28mm PET preform is the global benchmark for carbonated beverages. Its wider neck finish offers higher strength, better sealing, and superior carbonation retention.

| Technical Parameter | 25mm PET Preform | 28mm PET Preform |

|---|---|---|

| Bottle preform neck size | 25mm | 28mm |

| PET preform diameter | Smaller | Larger |

| PET preform weight | Lower | Higher |

| PET preform thickness | Optimized for lightweighting | Designed for pressure resistance |

| Preform neck finish comparison | Slim, cost-efficient | Robust, secure sealing |

For still water, the 25mm PET preform is widely considered the best PET preform size for 500ml bottle applications. Its lightweight design reduces cost and improves logistics efficiency.

When comparing 25mm PET preform vs 28mm PET preform for CSD, the 28mm option is clearly superior. Carbonated beverages require stronger neck finishes to prevent CO₂ leakage.

Juice packaging depends on viscosity and filling temperature. Both sizes are used, but premium juice brands often prefer 28mm for better pouring control.

For edible oils, the PET preform for oil packaging often favors 28mm neck finishes to handle viscous flow and prevent spillage.

From a production standpoint, PET preform molding efficiency plays a critical role. Smaller neck finishes usually enable faster injection cycles and lower energy consumption.

Preform crystallinity and clarity depend on cooling rates, mold design, and resin quality. Both sizes can achieve excellent optical clarity when processed correctly.

View Products

View Products

View Products

Understanding PET preform weight calculation is essential for cost control. Even a small difference in neck finish size can translate into significant annual resin savings.

A preform bottle weight comparison typically shows:

Both preform sizes undergo rigorous preform quality testing, including:

The preform size impact on bottle performance becomes evident during carbonation and transportation tests.

Modern packaging focuses heavily on sustainable PET preforms. Brands aim to reduce plastic usage while maintaining performance.

Choosing between 25mm vs 28mm PET preform depends on product type, brand positioning, and production priorities.

By understanding how to choose PET preform size, manufacturers can design optimized, reliable, and future-ready PET packaging solutions.

Copyright © 2026 Siddhartha International All Rights Reserved.